Get in touch! +91 9687731331 | +91 9687631331 | info@lodhapharma.com

What to Look for in a Vacuum Tray Dryer?

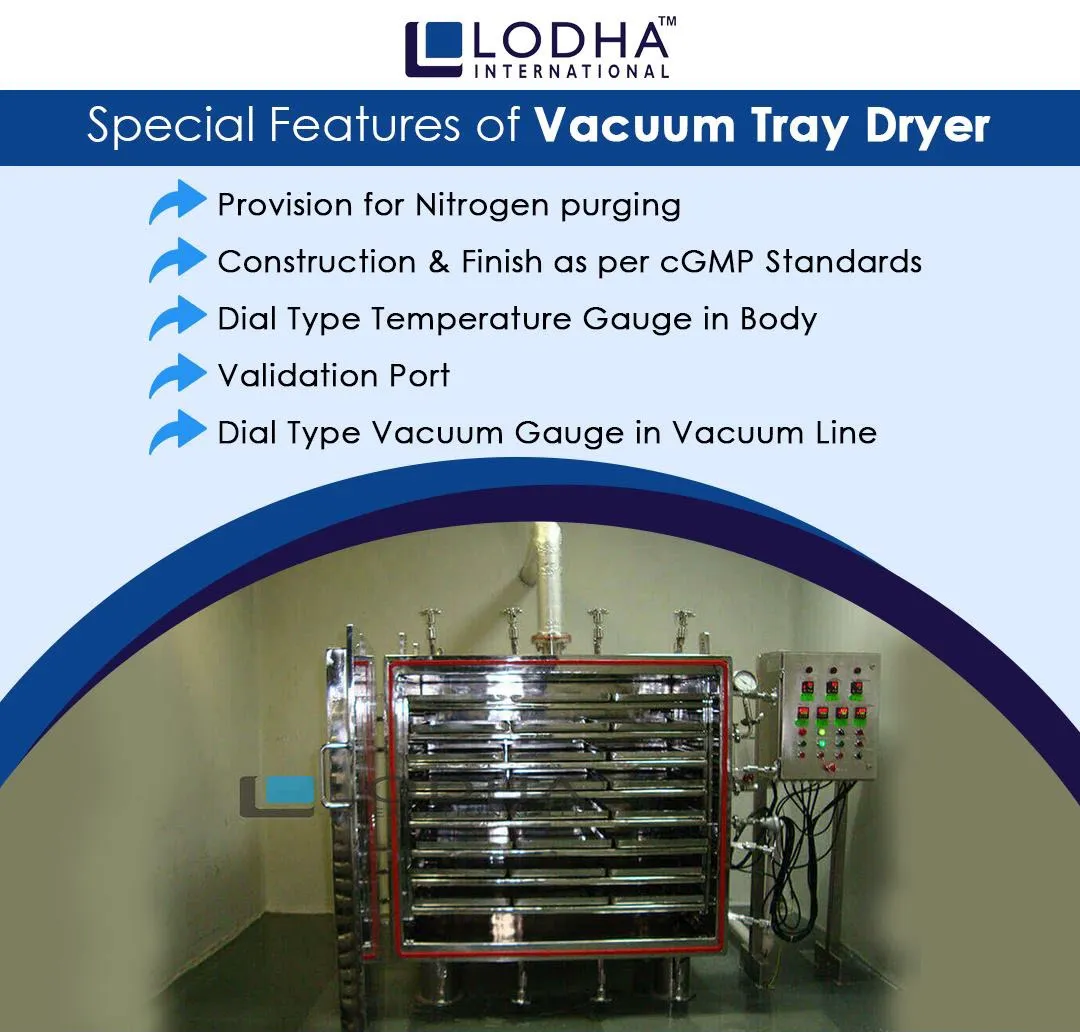

If you are looking for the right Vacuum Tray Dryer to meet your drying needs, you are in the right place. Lodha International LLP manufactures a wide range of equipment for the chemical, plastic, food, engineering, and defense industries. Listed below are some of the features of vacuum tray dryers. These include the Heating shelves, Directional vanes, Inlet and outlet nozzles, and Operating pressures.

Heating Shelves of Vacuum Tray Dryer

The vacuum tray dryer, is a type of batch dryer. It is a versatile piece of equipment used for drying solids and evaporating condensables from slurries. This high-tech dryer has individual, heated shelves that ensure the most uniform drying temperatures and pinpoint accuracy. These machines can also include distillation systems. These systems provide high vacuum and are ideal for degassing epoxies, silicones, and adhesives.

The heating shelves of a vacuum tray dryer are manufactured of a hollow material with inlet and outlet nozzles. The Inlet Header connects these nozzles to a heating fluid source. The heating fluid flows through the shelves in a serpentine motion, evenly heating the Trays placed on them. The heated media exits the cabinet through the Outlet Header, which is connected to the main inlet and outlet headers via a tri-clover fitting.

Vacuum Tray Dryer Directional Vanes

The best vacuum tray dryers have directional vanes to control air flow to trays. The trays may be lined with paper or other materials. Some trays may be supported by perforated steel or wire mesh. These trays can be placed in a chamber or in the dryer's main body. They have removable liners that prevent contamination. The trays also need to be replaced occasionally to keep them clean and dry.

Inlet and Outlet Nozzles of Vacuum Tray Dryer

A vacuum tray dryer is one of the most popular batch drying machines in the market today. The device is cylindrical or box-shaped with several trays for drying the product. The topmost shelf acts as a dummy to avoid powder escaping, and the lower shelves are hollow, with baffles and stiffeners to ensure a proper heat transfer. Every shelf has an inlet and outlet nozzle connected to an inlet header.

A vacuum tray dryer is a popular piece of laboratory equipment because of its many applications. It can be used to dry a wide variety of materials, including high-grade pharmaceuticals, foods, and other materials that are highly sensitive to moisture. A vacuum tray dryer is easy to maintain, as it has a flat, metallic door. A variety of power sources are available to accommodate a wide range of materials and processes.

Operating Pressures of Vacuum Tray Dryer

Operating pressures of a vacuum tray drying chamber are important to optimize the drying process of a sample. When the air velocity and the vacuum pressure are different, the moisture diffusivity of the sample decreases, and the drying time increases. The kinetics of the drying process are well described by a kinetic model based on the relationship between the air velocity and the vacuum pressure.

The drying process exhibits similar tendencies under atmospheric and vacuum pressures. The high temperature of air promotes rapid drying, but it also causes cube sides to harden, increasing the resistance to the moisture diffusion process. The low driving force reduces the drying rate in the final period of the drying cycle. Thus, lower system pressures are preferred for optimal drying. The lower the operating pressure of a vacuum tray dryer, the faster the drying process is.

Vacuum Tray Dryer Material Compatibility

The most common question asked by potential users is - "What's the material compatibility of a vacuum tray dryer?" This answer will depend on the type of product that's being dried. There are several different types of vacuum tray dryers, including bench-sized and commercial units. The first type of dryer uses mechanical agitation. This mechanical agitation helps dry the sample at a high temperature. Other types of dryers use a rotary drum or vacuum chamber.

The Bottom Line

The best tray dryers control the amount of air passing over the trays. Trays are often lined with paper, disposable paper, or other material. Trays are generally supported by wire mesh or perforated steel. The trays can be placed at different temperatures, so it's important to select a unit that can accommodate the drying process. While the operating temperature may be set to a low temperature, the capacity of the vacuum tray dryer must be sufficient to dry the materials.