Get in touch! +91 9687731331 | +91 9687631331 | info@lodhapharma.com

Semi Automatic Capsule Filling Machine

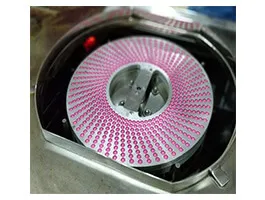

Semi-Automatic Capsule Filling Machine Model: LSCF is preferred for applications that require precise manufacturing methods for modern pharmaceutical procedures. The Semi Auto. capsule filling machine allows for higher degree of automation when compared to manual capsule filling machine, thus ensuring higher level of filling weight accuracy. This capsule filling machine is deemed apt for the operation of capsule filling of varying sizes with powders, granules or pellets. With the GMP standards manufacturing methods employed for semi automatic capsule filling machine, it comes with an all Stainless-Steel covering. The machine is capable of yielding high outputs, i.e. 25000 to 47000 capsules/hour that depends on the size of capsule and operator’s skill-set. It performs the operation of on line polishing & sorting. Polishing of the tablets do not require operators and there is no need for a separate storage for filled capsule. Manufacturer of semi-automatic capsule filling machine has a four speed auger that allows it to operate and fill different types of powder & pellets. Filling table of the machine has variable speed that aids in achieving high dosage accuracy. Semi automatic capsule filler incorporates automatic capsule loading system to ensure faster, safer, closure and ejection of filled capsules. It also has an automatic drug hopper in-feed mechanism to eliminate any variation in weight and thus ensures in high productivity.

The semi-automatic capsule line is equipped with automatic Capsule conveying system that transports the completely filled capsules to capsule polishing machine from semi automatic capsule filling machine or where they need to convey. The process is completely automatic without human hands interactions with the help of a pump that sucks and move the filled capsules. automatic polishing machine for cleaning the capsules. It uses a rotating brush to carry out the operation. The polishing chamber comprises of a rotating spiral brush that removes the powder particles from the surface of the capsules after being fed. This chamber is also connected to the vacuum cleaner to suck out the de-dusted powder in order to clean the chamber. The semi auto capsule filling line also comprise of an empty capsule ejector. It checks whether the capsules are filled or not and ejects those capsules that are empty due to some machine error. Capsule ejection takes place due to the air force applied on the capsules. Damage capsule sorter removes the diametrically distorted capsules from the lot and only allows the perfect sized capsules to pass through. It is a part of semi-automatic capsule filling line machine and ensures only well proportionate & sized capsules.

The entire arrangement of the semi-automatic capsule filler is quite uncomplicated. At first, the capsules are transferred to the hopper whose size varies from 00 to 5. In a separate corkscrew driven hopper, the powders are again transferred that ensures a constant fill in every single capsule. Vacuum sucker is also utilized in this process for the purpose of sorting the capsules individually and later fill them into the loading rings (size differing from 00 to 5). The operator, then makes use of vacuum in order to bifurcate the capsules.

After the capsules get separated through the above process, loading rings are pulled apart that releases only the bottom section. In the filling part of the machine, this bottom section is stationed along with loading rings after which the operator begins the process of filling. The capsules rotates below the filler as they move across the capsules. With the help of corkscrew, these powders are evenly pushed down into the capsules. Hence, it is made sure that every capsule is similar in weight and size. The loading rings are then later, placed back together as they were before in the sealing section of the capsule filling machine. The guards are closed by the operator, once these rings get aligned. For the purpose of sealing the capsules, air pressure is used after the closure of guard and then the capsules are finally removed from the loading ring.

The filling line accommodates a capsule polishing machine that consists of a set of corkscrew brush bristles and a dust extractor unit. Any presence of dust particles are removed with the help of vacuum to achieve capsules of superlative quality.

Thank you for watching our video. If you would like any more information about our products, please feel free to contact us

Salient Features of Semi Automatic Capsule Filling Machine

Technical Specification of Capsule Filler Machine (Semi Automatic):

| Sr. No. | Model | LSCF – 35 | LSCF - 45 |

| 1 | Production Output /hr | Up to 35,000 capsules | Up to 45,000 capsules |

| 2. | M.O.C. of Loading Ring M.O. C. of contact parts |

Magnesium Alloy Stainless Steel 316 |

Magnesium Alloy Stainless Steel 316 |

| 3. | Number of Ring | Single | Double |

| 4. | Number of Holes | Size 00: 480 Size 0: 600 Size 1, 2, 3, 4 & 5: 720 |

Size 00: 480 Size 0: 600 Size 1, 2, 3, 4 & 5: 720 |

| 5. | Power Supply | 3 Phase, 415 Volts, 50 Hertz | 3 Phase, 415 Volts, 50 Hertz |

| 6. | Compressed Air | 8 CFM | 8 CFM |

| 7. | Machine Dimensions Length (In mm) Width (In mm) Height (In mm) |

1950 1200 1800 |

2650 1250 1800 |

| 8. | Net Weight in Kgs. | 1100 | 1250 |

Operating Procedure of Semi-Automatic Capsule Filling Machine

- Feed empty capsules in the hopper

- Put on loading ring on loader

- Push the lever to load capsules in loading ring

- Remove the loading ring and separate its upper and lower part manually (to separate capsule bodies and caps)

- Put the lower part of loading ring on the machine for filling and fill the powder in hopper

- Press powder filling button to fill powder in capsule bodies

- Join upper and lower parts of loading ring and send them for sealing

- Loading ring will come with sealed capsules and it will turn upside down for ejection

Benefits of Semi Automatic Capsule Filling Machine

- Simple Operation

- Easy Maintenance

- Power Saving

- High Filling Accuracy

- Quick and safe operation of closing and ejection

- Easy to upgrade