Get in touch! +91 9687731331 | +91 9687631331 | info@lodhapharma.com

Top Labeling Machines from India's Leading Manufacturer

Best Labeling Machine Manufacturer for various industries

LODHA International LLP is one of the leading manufacturers of labeling equipment. The pharmaceutical sector is a highly regulated, fast-paced industry where quality and precision are crucial. In this industry, labeling is essential for maintaining regulatory compliance, brand presence, and product identification. Established in 2008, Lodha has become a leader in manufacturing packaging machinery for the pharmaceutical, healthcare, veterinary, cosmetic, chemical, and biotech industries. With a focus on delivering high-performing, reliable, and versatile machinery, LODHA International LLP offers a wide array of labeling machines designed to cater to the specific needs of the industries they serve. In this, we will explore the top labeling machines from Lodha and how they can benefit manufacturers across various sectors.

Importance of Labeling Machines in the Pharmaceutical Industry

Pharmaceutical manufacturing relies heavily on labeling machines since they manage one of the most important components of packaging: giving precise and understandable product information. These devices are essential for providing that the goods fulfill regulatory requirements, which frequently call for accurate and clearly specified labels on each unit. For instance, the pharmaceutical industry demands complete labels that include the drug's name, batch number, expiration dates, and other important details.

By automating the labeling process, manufacturers can:

- Improve production efficiency

- Reduce human error

- Increase production speed

- Improve label accuracy and uniformity

- Comply with industry regulations and guidelines

Top Labeling Machines from Lodha International LLP

Lodha has designed its range of labeling machines to meet the Varies needs of various industries. Below are some of the top labeling machines offered by LODHA International LLP:

-

Automatic Ampoule Labeling Machine

The Automatic Ampoule Labeling Machine is widely used in the pharmaceutical industry to label small vials and ampoules. Because of their small size and the essential nature of their contents, these containers require very exact and precise labeling.

- High-speed performance : This machine can handle hundreds of ampoules per minute, making it perfect for high-volume production.

- Versatile design : It is compatible with different types and sizes of ampoules.

- Error-free labeling : Equipped with advanced sensors, this machine minimizes labeling errors, making sure all ampoules have consistent labels.

-

Sticker Labeling Machine

Lodha’s Sticker Labeling Machines are used across various industries like promotions, trade exhibitions, product launches, special orders, pharmaceuticals, cosmetics, food, and beverages. These machines are designed to apply labels automatically to different products, whether they are cylindrical or flat.

- Multi-use functionality : The machine can handle various types of labels, including self-adhesive, paper, and plastic labels.

- User-friendly operation : It features easy-to-use controls that allow operators to set up and run the machine with minimal training.

- High precision : It applies labels with high accuracy, making sure that the labels are placed at the correct angle and position.

-

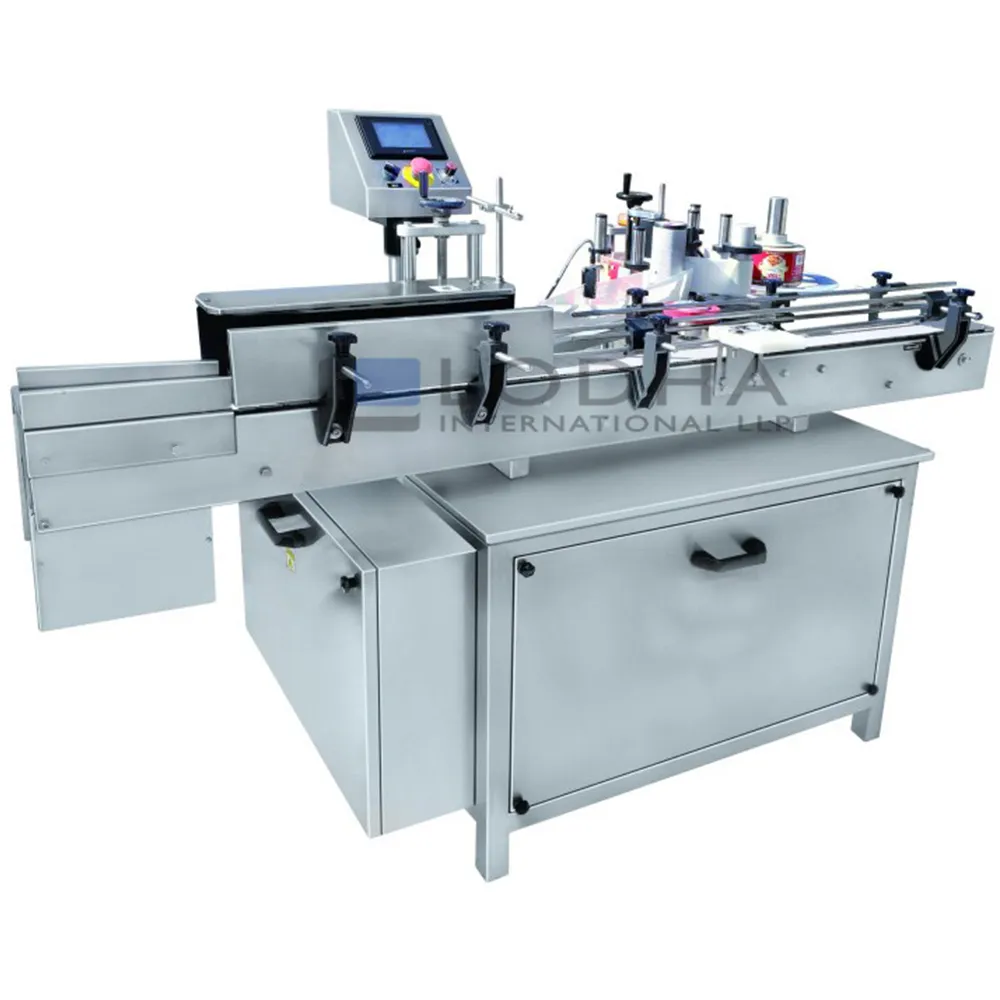

Bottle Labeling Machine

The Bottle Labeling Machine is specifically designed to label bottles of varying shapes and sizes. It is widely used in industries like food and beverages, chemicals, and pharmaceuticals, where labeling on bottles is a common requirement.

- Adaptable for different bottles : This machine can handle round, square, and even irregularly shaped bottles.

- Efficient speed : It is capable of labeling bottles at high speed, keeping up with the production lines.

- Consistency : The machine makes sure uniform label placement on every bottle.

-

Vial Labeling Machine

The Vial Labeling Machine is a high-precision machine used to label small cylindrical containers, such as vials used in pharmaceutical and healthcare products.

- Compact and efficient design : This machine is ideal for high-speed production lines that deal with small vials.

- Accurate labeling : Even with small-sized vials, the machine makes sure precise labeling, meeting industry regulations.

-

Automatic High-Speed Labeling Machine

Lodha’s Automatic High-Speed Labeling Machine is designed for industries that require fast and efficient labeling for large production runs. This machine is suitable for labeling on bottles, vials, ampoules, and containers of various shapes and sizes.

- Unmatched speed : It can label thousands of units per hour, making it a perfect fit for high-demand manufacturing environments.

- Flexible design : This machine can handle a wide range of labeling tasks, including those involving different materials and label types.

- Error detection : It includes sensors to detect any missing labels or misaligned labels, reducing wastage and increasing efficiency.

Key Features of Lodha Labeling Machines

LODHA International LLP designs its labeling machines with several key features that benefit manufacturers in different industries. These features make sure reliability, precision, and ease of use. Some of the primary features include:

- High-Speed Operation : All machines are built to operate at high speeds to meet the demands of large-scale production lines.

- User-Friendly Interface : Lodha labeling machines come equipped with intuitive and easy-to-use control panels, making it simple for operators to manage different tasks and configurations.

- Durability and Low Maintenance : Made from high-quality materials, these machines are built to last and require minimal maintenance, reducing downtime and costs.

- Advanced Sensor Technology : Lodha International LLPs use sensors that automatically detect the position and orientation of the product, making sure precise label application every time.

- Flexibility : They are versatile enough to handle a wide variety of container shapes, sizes, and materials, making them suitable for a range of industries beyond pharmaceuticals, including cosmetics, food, beverages, and chemicals.

Benefits of Using Lodha Labeling Machines

Manufacturers can benefit from a number of labeling machine advantages offered by LODHA International LLP. Here are a few of the principal advantages:

-

Improved Efficiency

Automation of the labeling process significantly boosts productivity by eliminating manual labor and reducing the time required for labeling each product. Lodha International LLPs are built for high-speed labeling without sacrificing accuracy or quality.

-

Consistency in Labeling

Manual labeling can lead to inconsistencies in the placement and accuracy of the labels, resulting in poor presentation and compliance issues. With Lodha's advanced labeling machines, manufacturers are guaranteed consistent, high-quality labels on every unit.

-

Reduced Error and Waste

Human error during labeling can lead to product recalls, wasted labels, and ruined packaging. Lodha International LLPs are designed to minimize errors by using advanced sensor technology and automated systems to detect any issues during the labeling process.

-

Cost-Effectiveness

By improving efficiency, reducing errors, and increasing throughput, Lodha labeling machines offer a cost-effective solution for manufacturers. The investment in high-quality labeling machinery pays off in the long term with improved productivity and reduced labor costs.

Conclusion

In today’s fast-paced manufacturing environment, investing in high-quality labeling machines is essential for companies that want to stay ahead of the competition. With a range of top-of-the-line labeling solutions, LODHA International LLP is the ideal partner for manufacturers in various industries. Lodha provides the ideal machine to fulfill your demands, whether you need ampoules, vials, bottles, or other containers precisely labeled. LODHA International LLP stands out in the industry due to its commitment to providing efficient, reliable, and high-performance labeling machines. By choosing Lodha’s machines, manufacturers can improve their operational efficiency, reduce errors, and meet all regulatory requirements with ease.

For more information about LODHA International LLP range of labeling machines or to discuss how we can help improve your production line, please contact us at +91 9537131331 or email us at info@lodhapharma.com. We are here to provide the best packaging solutions for your business.