Get in touch! +91 9687731331 | +91 9687631331 | info@lodhapharma.com

The Complete Guide to Fluid Bed Dryers

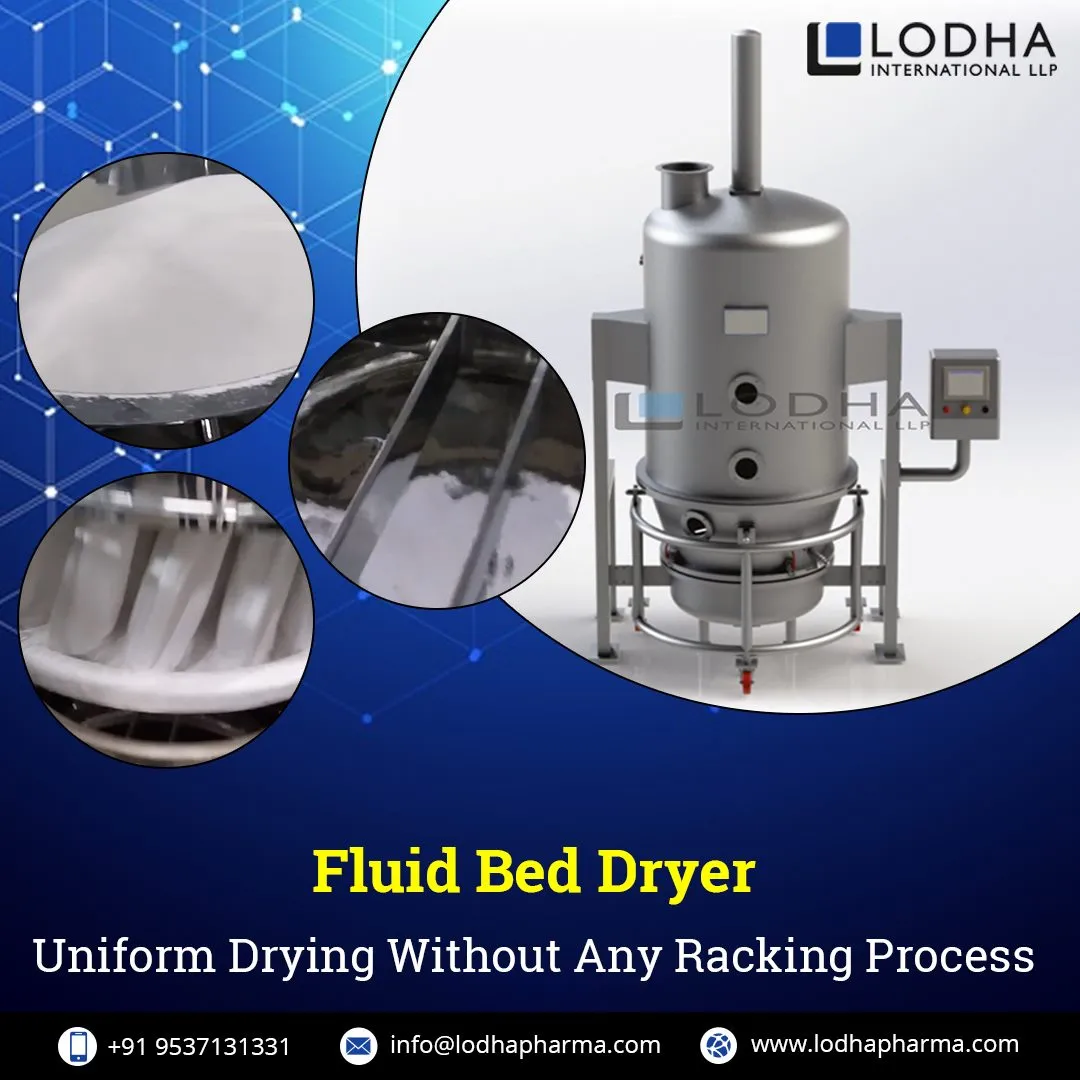

If you are in the pharmaceutical industry, you require cutting-edge machines to ensure that the products are formulated and packaged efficiently. One of these advanced machines includes a fluid bed dryer. This equipment helps to reduce the moisture content of powder and granules. Want to learn more? Here’s a quick guide to help you know everything about fluidized bed drying machine!

- What are Fluid Bed Dryers Used for?

- What is the Design Structure of a Lab Fluid Bed Processor?

- How Does a Lab Fluid Bed Dryer Works?

- How Does Fluid Bed Dryer Affect the Final Product?

- What Are the Advantages of Using a Fluid Bed Drying Machine?

What are Fluid Bed Dryers Used for?

Fluid bed dryers have several applications that assist in drying materials such as powders, granules, fertilizers, plastics, and many more! Material forms such as powders and granules can be hard to work with as they lack uniformity and flow.

With a multi-functional processor, such as fluid bed dryers, you can consistently remove moisture content. They come equipped with spray dryers and granulation systems to ensure appropriate drying, finishing, and granulation of substances. That way, transportation and handling of hard materials become easier.

What is the Design Structure of a Lab Fluid Bed Processor?

There are many types of fluid bed dryers available for your unique business needs. They come with several custom adjustments and capacities to treat materials. The basic design structure of a fluid bed drying machine is as follows:

-

Air Handling Unit: This unit helps in providing the required temperature needed to dry the wet particles. Wet powders are conveyed over the bed, and then heated air is supplied for drying. There are several filters, dehumidifiers, and fans available to amplify the process.

-

Main Tower: It has a base part, product container, expansion and filter chamber.

-

Control Panel: Advanced fluid bed dryers have a control panel to help you control the flow rate and temperature. It makes the process more efficient.

How Does a Lab Fluid Bed Dryer Works?

A lab fluid bed dryer work on the principle of fluidization. This is how the drying process occurs:

-

During the drying process, hot air gets through the holes of the perforated bed. The air is blown upwards with a higher velocity that makes the particles suspended in the air stream.

-

The airflow rate and the temperature is adjusted through the control panel on a continuously vibrating bed. The increasing airflow and constant velocity make it possible for fluidization of the bed.

-

The hot air sucks all the moisture present in the granules leaving fine particles.

How Does Fluid Bed Dryer Affect the Final Product?

The equipment requires careful handling to achieve the desired result. Also, you should pay attention to several parameters for optimum performance. Here’s what you need to consider before working with a fluid bed drying machine:

-

Equipment Apparatus: The nozzle height along with the position of the air distribution plate can affect the efficiency of the process.

-

Operating Elements: You need to decide on the ideal temperature range. This factor depends on the nature of the material. Also, understand when you should increase the airflow rate for moisture transfer.

-

Consider Your Product: Before the operation process begins, ensure that you know about the moisture content, batch size, and other essential details.

The way you operate your fluid bed dryer will affect the quality of the final product. Hence, consider consulting with experts for the best experience.

What Are the Advantages of Using a Fluid Bed Drying Machine?

With technical advancements, there are many advantages of using a fluid bed dryer. Let’s dive into the top benefits of using them for your business!

-

Ability to Handle Various Materials: A lab fluid bed dryer can handle several industrial requirements. It is compatible with different materials and offers excellent thermal efficiency.

-

Energy Efficient: With many system integration capacities, you can reduce minimal downtime making it energy-efficient equipment. In comparison with other traditional drying machines, this equipment has a smaller footprint.

-

Accurate Control: You can monitor the process and control the residence time and temperature as per your requirements.