Get in touch! +91 9687731331 | +91 9687631331 | info@lodhapharma.com

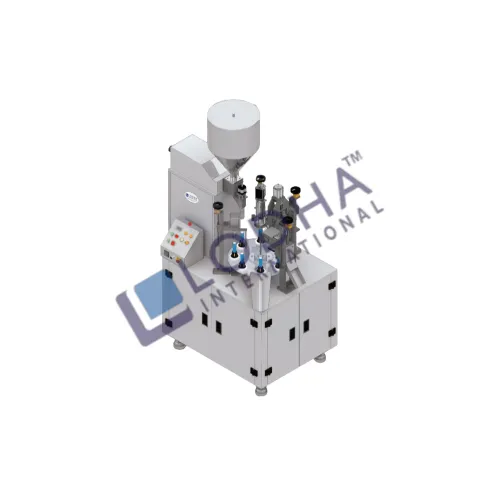

Semi Automatic Rotary Tube Filling Machine

Lodha International LLP is the leading semi automatic rotary tube filling machine manufacturer, offering complete solutions for the food, cosmetics, and pharmaceutical industries. Our semi-automatic rotary tube filling machine is designed to produce up to 80 tubes per minute, making it both reliable and highly efficient. The machine is built for ease of use, with quick-change parts that minimize downtime and simplify operation. Featuring an auto-drip-free filling mechanism, this machine make sure a clean and precise filling process, making it a preferred choice for many businesses.

The machine incorporates a temperature-controlled, compressive system for filling and crimping operations, enhancing its variety. An advanced tube alignment system guarantees precise filling, while the full-size opening of the front guard allows for easy maintenance and quick changeovers. The primarily mechanical design reduces the need for extensive training and maintenance, making it an excellent investment for food, cosmetics, and pharmaceutical industries. Its volumetric dosing method is particularly suited for filling thick substances such as creams and ointment filling, gels, pastes, and balms.

Salient Features of Semi Automatic Rotary Tube Filling Machine:

Process Operation of Semi Automatic Rotary Tube Filling Machine

Lodha International LLP's semi-automatic rotary tube filling machine offers a smooth and effective operation, making it suited for a wide range of industrial uses. It features an easy-to-use design and reliable results. During the process, tubes are manually loaded into the machine’s rotary indexing table. The rotary tube filling machine accurately fills each tube with a specified amount of product, thanks to its volumetric dosing system, ensuring consistent quality. The machine's auto-drip-free mechanism prevents any mess during the filling process. Once filled, the tubes are sealed using a Leister heater and blower hot air system, which make sure a secure seal. The tubes are then cooled by water circulation around the exterior, enhancing the quality of the seal. The semi-automatic rotary tube filling machine is equipped with a production counter on the control panel, allowing operators to monitor the total number of tubes filled. The machine's design includes a "No Tube, No Fill" mechanism, ensuring efficient use of resources.

As a leading rotary tube filling machine manufacturer and exporter, we offer pharma machine that meets the highest levels of efficiency and durability. The machine's easy maintenance and quick part changeover capabilities make it an excellent choice for pharmaceutical machines looking to optimize their production processes.

Technical Specification of Semi Automatic Rotary Tube Filling Machine:

| Technical Specifications: LI-STF 8 | |

| Model No. | LI-STF 8 |

| No. of Filling Head | Single |

| No. of Station | 8 |

| Production Output (Per Min) | 25 - 30 tubes |

| Tube Diameter | 12mm to 50mm |

| Tube Length | 50mm to 200mm |

| Tube Loading System | Manual |

| Tube Orientation | Manual |

| Filling Range | 3gm to 250gm** |

| Compressed Air Requires | 6 CFM |

| Power Consumption | 1.5 H.P. |

| Electric Characteristic | 440V, 3 Phase, 50Hz, 4 Wire System |

| Net Weight | 250 Kgs. |

| Gross Weight | 375 Kgs. |