Get in touch! +91 9687731331 | +91 9687631331 | info@lodhapharma.com

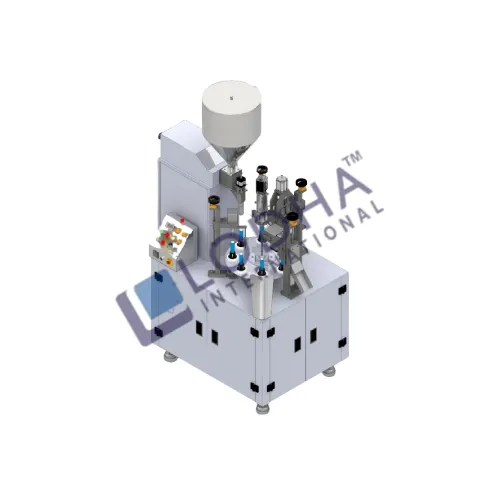

Semi Automatic Cosmetic Tube Filling Machine

Lodha International LLP is the top semi automatic cosmetic tube filling machine manufacturer, offering innovative solutions to improve your production process. Investing in a semi-automatic cosmetic tube filling and closing machine can significantly increase your packaging efficiency, allowing you to fill and seal tubes quickly and easily. This machine's high throughput and minimal maintenance requirements enable the production of large quantities in a short time. The dispensed quantity into each tube is adjustable, improving consistency and precision across all batches. The machine produces the same accuracy as manual filling, reducing variability and delivering quality results. By automating the filling and sealing process, the semi automatic cosmetic tube filling machine reduces the risk of workplace injuries, as employees are less likely to be involved directly in the operation. This not only enhances workplace safety but also lowers the financial impact associated with potential accidents. The machine combines several functions, including cleaning, filling, sealing, and labeling tubes, thereby boosting overall production efficiency.

The process starts with the machine filling the tubes to a specific level. Once filled, the machine seals the tubes immediately to prevent leaks and waste. There are various methods for filling cosmetic tubes, and the degree of automation can vary between different manufacturers. Lodha International LLP assures that its semi-automatic cosmetic tube filling and closing machine offers the flexibility and efficiency needed for modern production demands.

Salient Features of Semi Automatic Cosmetic Tube Filling Machine:

Process Operation of Semi Automatic Cosmetic Tube Filling Machine

The semi automatic cosmetic tube filling machine process operation starts with placing tubes manually into the machine. The machine then accurately fills each tube to the desired volume. Using a pneumatic cylinder, the machine seals the tubes, codes them, and cuts off any excess material. Leister's heater and blower system make sure the tubes are sealed efficiently and securely. A water pump cools the tubes from the outside, resulting in a better seal quality. The production counter on the control panel displays the number of tubes filled, allowing operators to monitor productivity easily. The semi automatic cosmetic tube filling and closing machine is designed for minimal maintenance, maintaining continuous operation and high efficiency.

Technical Specification of Semi Automatic Cosmetic Tube Filling Machine:

| Model No. | LI-STF 8 |

|---|---|

| No. of Filling Head | Single |

| No. of Station | 8 |

| Production Output (Per Min) | 25 - 30 tubes |

| Tube Diameter | 12 to 50 mm |

| Tube Length | 50 to 200 mm |

| Tube Loading System | Manual |

| Tube Orientation | Manual |

| Filling Range | 3 gm to 250 gm |

| Compressed Air Requires | 6 CFM |

| Power Consumption | 1.5 H.P. |

| Electric Characteristic | 440V, 3 Phase, 50Hz, 4 Wire System |

| Net Weight | 250 Kgs. |

| Gross Weight | 375 Kgs. |