Get in touch! +91 9687731331 | +91 9687631331 | info@lodhapharma.com

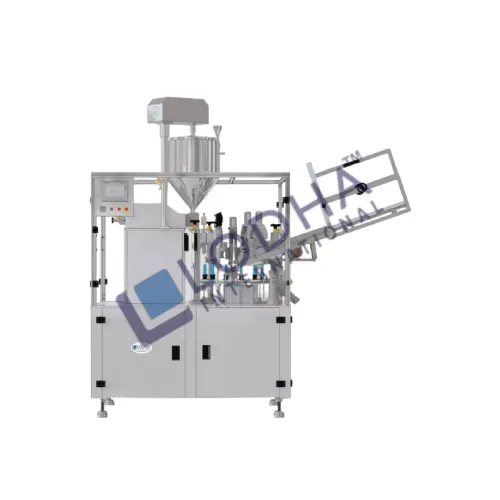

Rotary Aluminium & Plastic Tube Filling Machine

Lodha International LLP is the top rotary aluminium & plastic tube filling machine manufacturer, delivering innovative solutions for the pharmaceutical industry. Our rotary aluminium, plastic tube filling machine is capable of producing over 60+ tubes per minute, making it both reliable and easy to operate. This machine features an auto-drip-free filling mechanism and a user-friendly design, making it a top choice for the pharma industry. Its comprehensive solution for filling and crimping operations make sure efficiency and precision. The machine has a larger than normal front guard opening for easy maintenance and part swaps, and an enhanced tube alignment system for greater accuracy.

This rotary aluminum, plastic tube filling machine is excellent for use in medical, cosmetic, and culinary uses. Its volumetric dosing technique makes it perfect for filling a variety of thicker products such as creams, ointments, gels, pastes, and balms. The compact design of these sealing devices makes them simple to use despite their advanced capabilities. Operating in a semi-automatic mode, the machine requires only one person to initiate the process, after which it handles the filling and sealing autonomously. The machinery can handle tubes of various diameters, shapes, capacities, and styles. The machine’s computerized temperature control is both precise and efficient, helping to conserve energy. Its simplicity of use means minimal human input is required: once the settings are adjusted, the machine runs itself.

Salient Features of Rotary Aluminium & Plastic Tube Filling Machine:

Process Operation of Rotary Aluminium & Plastic Tube Filling Machine

The rotary aluminium and plastic tube filling machine from Lodha International LLP keep improving and efficient operation, making it suited for a variety of industries. During the process tubes are manually loaded into the machine’s rotary indexing table. The rotary aluminium, plastic tube filling machine accurately fills each tube with a specified amount of product, making consistent quality.

The machine's auto-drip-free mechanism prevents any mess during the filling process. Once filled, the tubes are sealed using a Leister heater and blower hot air system, which make sure a secure seal. The tubes are then cooled by water circulation around the exterior, improving the quality of the seal. The rotary aluminium & plastic tube filling machine is equipped with a production counter on the control panel, allowing operators to monitor the total number of tubes filled. The machine's design includes a "No Tube, No Fill" mechanism, ensuring efficient use of resources.

As a leading rotary aluminium & plastic tube filling machine manufacturer and exporter, Lodha International LLP offers pharma machine that meets the highest standards of efficiency and reliability. The machine's easy maintenance and quick part changeover capabilities make it an excellent choice for the pharmaceutical industry looking to optimize its production processes.

Technical Specification of Rotary Aluminium & Plastic Tube Filling Machine:

| Model No. | LI-STF 8 | LI-TUBO 12 |

|---|---|---|

| No. of Filling Head | Single | Single |

| No. of Station | 8 | 12 |

| Production Output (Per Min) | 25 - 30 tubes | Up to 50 tubes |

| Tube Diameter | 12 to 50 mm | 12 to 50 mm |

| Tube Length | 50 to 200 mm | 50 to 200 mm |

| Tube Loading System | Manual | Automatic |

| Tube Orientation | Manual | Automatic |

| Filling Range | 3 gm to 250 gm | 5 gm to 250 gm** |

| Compressed Air Requires | 6 CFM | 12 Bar |

| Power Consumption | 1 H.P. | 1 H.P. |

| Electric Characteristic | 440V, 3 Phase, 50Hz, 4 Wire System | 440V, 3 Phase, 50Hz, 4 Wire System |

| Net Weight | 250 Kgs. | 465 Kgs. |

| Gross Weight | 375 Kgs. | 580 Kgs. |