Get in touch! +91 9687731331 | +91 9687631331 | info@lodhapharma.com

Revolutionizing Pharmaceutical Manufacturing with Tablet Coater Technology

Pharmaceutical manufacturing is a crucial aspect of the healthcare industry as it ensures that necessary medications are available to people who need them. The use of tablet coater technology has revolutionized pharmaceutical manufacturing in recent years, making the process more efficient, cost-effective, and safer.

Pharmaceutical manufacturing involves the production of drugs and other medical products through several stages, including drug discovery, development, production, and distribution. One of the critical aspects of pharmaceutical manufacturing is the coating of tablets to protect them from moisture, light, and other environmental factors. In recent years, the use of tablet coater technology has revolutionized pharmaceutical manufacturing, making it more efficient, cost-effective, and safer.

Advantages of Tablet Coater Technology in Pharmaceutical Manufacturing

The use of tablet coater technology in pharmaceutical manufacturing has several advantages, including:

Tablet Coater Technology Reduce Costs

Tablet coater technology can also reduce the costs associated with pharmaceutical manufacturing. The automation of the coating process can reduce the need for manual labour, which can reduce labour costs. The use of tablet coater technology can also reduce the number of raw materials required, which can reduce material costs.

Managing production is challenging for many pharmaceutical companies. Often the decisions made impact time-to-market, budgets and product margins. Advanced tablet-coating technologies increase manufacturing efficiency by improving coating uniformity, reducing coating solution waste, and minimizing cleaning and maintenance. This reduces operating costs and improves productivity.

High-efficiency coaters have coating pans that are longer in length but smaller in diameter, allowing the tablets to move more frequently into the spray zone and eliminating the slow-moving zones that often occur when using conventional tablet coaters.

Tablet Coater Machine Improves Efficiency

Tablet coater technology can significantly improve the efficiency of the pharmaceutical manufacturing process. The coating process can be automated, reducing the need for manual labour and improving the speed and accuracy of the process. The use of tablet coater technology can also reduce the time required for the coating process, making it possible to produce more tablets in a shorter amount of time. This requires advanced coating technologies that reduce waste, improve processing efficiency, and ensure quality.

Coatings are used to protect the active ingredient (API) from degradation and to enhance its performance and stability. They can also be used to mask the taste, odour, or colour of the tablets and to control drug release.

Tablet Coater Technology is Flexible

Tablets are a very flexible dosage form. They allow for on-demand production, reducing development lead times. They are small in volume and can be produced with a variety of APIs.

The flexibility of these tablets also enables on-demand formulation testing. This allows for a more adaptive approach to a trial and can save time and resources.

In addition, the technology can create a wide range of release kinetics and modes. This allows for the ability to tailor the release profile of the drug and is ideal for formulations containing active pharmaceutical ingredients (APIs).

Applications of Tablet Coater Technology

Tablet coater technology has a wide range of applications in the pharmaceutical industry. One of the most significant applications is in the production of controlled-release tablets. Controlled-release tablets are designed to release the active ingredient in a controlled manner over some time, improving patient compliance and reducing side effects. Another application of tablet coater technology is in the production of taste-masked tablets. Some drugs have an unpleasant taste, which can make them difficult to administer. Tablet coater technology can mask the taste of the drug, making it more palatable for patients.

Future of Tablet Coater Technology

Tablet coater technology is still evolving, and there are several areas where it can be improved. One area of improvement is the development of more efficient coating materials. New coating materials can improve the coating process's efficiency, reduce production costs, and provide additional functions.

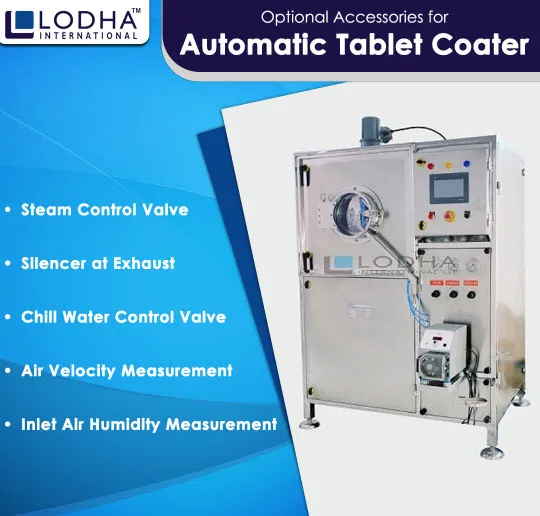

Another area of improvement is in the development of more advanced tablet coater machines. New machines can provide better control over the coating process, which can improve the quality and consistency of the coated tablets.

Tablet coater technology has revolutionized pharmaceutical manufacturing by providing a cost-effective, efficient, and customizable solution for coating tablets. With the continued development of more efficient coating materials and advanced tablet coater machines, the future of tablet coater technology looks bright.