Get in touch! +91 9687731331 | +91 9687631331 | info@lodhapharma.com

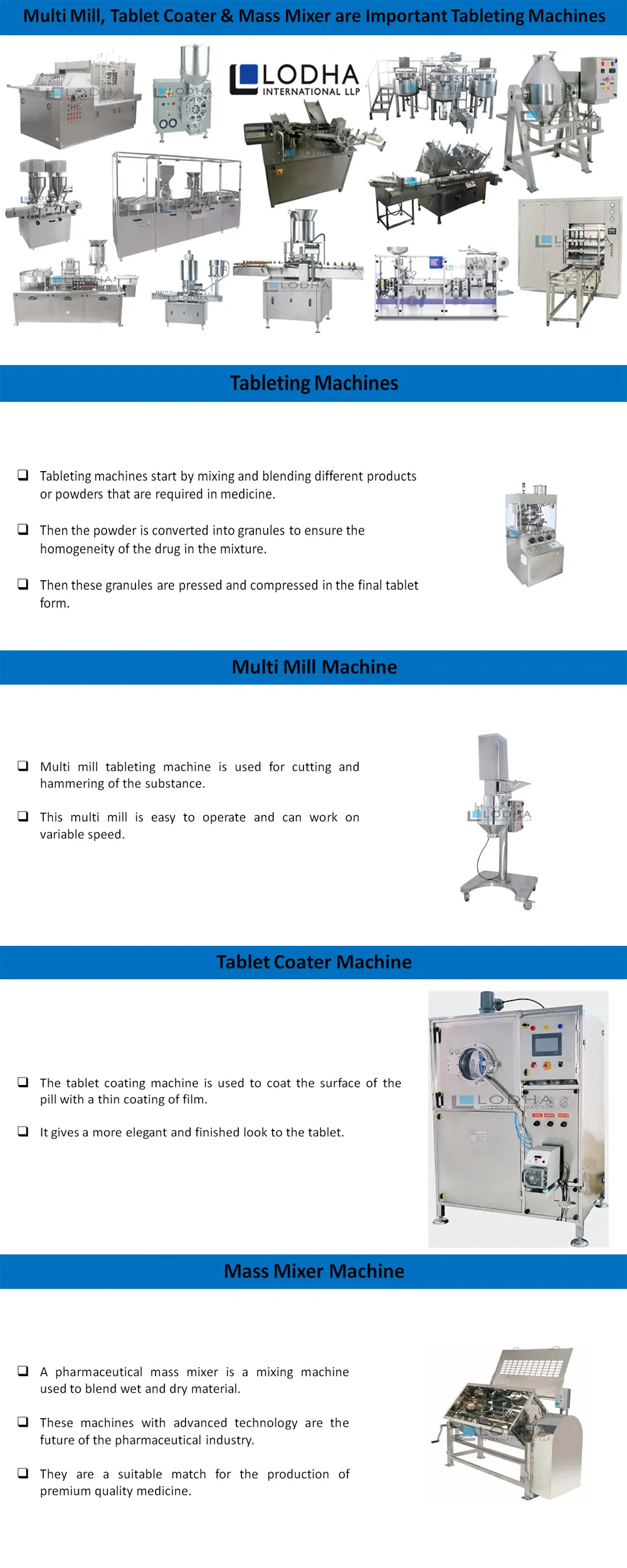

Multi Mill, Tablet Coater & Mass Mixer are Important Tableting Machines

Tableting is a method through which medicines are pressed into tablets. These tablets need to be made in the size and shape which can be swallowed easily. Machines used for the purpose are tableting machines. Manufacturing solid forms of tablets is a complex and multi-stage process. The physical characteristics of the material are changed several times before the formation of final consumable medicine.

Tableting Machines

Making tablets is a multi-stage process. A different mechanism is used in every step of the process. Machines also vary according to the material that needs to be converted into the tablet. These machines are durable and give maximum production. Tableting machines start by mixing and blending different products or powders that are required in medicine. Then the powder is converted into granules to ensure the homogeneity of the drug in the mixture. Now, these granules need to be dried so that the quality of the medicine remains intact. Then these granules are pressed and compressed in the final tablet form.

Different Tableting Machines

Before moving further in the process, these tablets are tested to assure their strength. Now excess powder is dusted off from these tablets and is proceeded for the packaging process. As these machines play an important role inthepharmaceutical industry, they need to be maintained in proper hygienic conditions. Let’s have a look at important machines used in this process.

Multi Mill Machine

Multi mill tableting machine is used for cutting and hammering of the substance. It means, first, thesubstance is cut into small pieces and then particle size is reduced so that it can be passed through a screen to get the required size. It operates on the principle of variable force swing beaters which have both knife and impact edges rotating within a selected area. This area has pores in them which make it possible to achieve the desired size of the granules. Wet material can also be milled through this multi millmachine. Hard granules are obtained after processing. This multi mill is easy to operate and can work on variable speed.

Tablet Coater Machine

The tablet coating machine is used to coat the surface of the pill with a thin coating of film. This film masks the color, smell, and taste of the drug. It also prevents the medicine from any physical or chemical harm. The coating is done to keep the different components of medicine integrated and control its release after its consumption. It gives a more elegant and finished look to the tablet. The coating machine works on a simple principle and applies the coat in the form of a solution to a group of tablets spread on the tablet coater machine’s bed. Then these tablets are passed through a heated vent which evaporates the solvent. The coating is uniformly spread on medicine by the movement of the bed.

Mass Mixer Machine

A pharmaceutical mass mixer is a mixing machine used to blend wet and dry material. It is fitted with a powerful gear drive and a mixing paddle. These machines are usually constructed with high-grade stainless steel which makes them durable and corrosion-proof. According to your needs, you can get a single-speed mixer or multi-speed. It consists of a mixing drum that comes with a see-through cover. To ensure safety, the machine does not start until the cover is properly closed. This drum can be tilted for easy loading and unloading of the product. Parts of the machine can be removed and cleaned easily for the maintenance of cleanliness.

These machines with advanced technology are the future of the pharmaceutical industry. They are a suitable match for the production of premium quality medicine.