Get in touch! +91 9687731331 | +91 9687631331 | info@lodhapharma.com

Manual Capsule Filling Machine - Pharmaceutical History

Necessity is mother of invention. The evolution of capsules as a drug delivery method was driven by a need for an easier and user friendly way to administer poorly tasting medicines and chemicals to the body that would otherwise be very hard to swallow.

It was noted that many people were neglecting to follow through with the treatment protocol due to taste and texture of the medicine being simply abhorrent and a torturous exercise.

With the invention of the capsule, patients were able to take medicine orally and this made treatment less invasive compared to use of suppositories and needle injections. With time, the use of capsules has become a popular option to the general public.

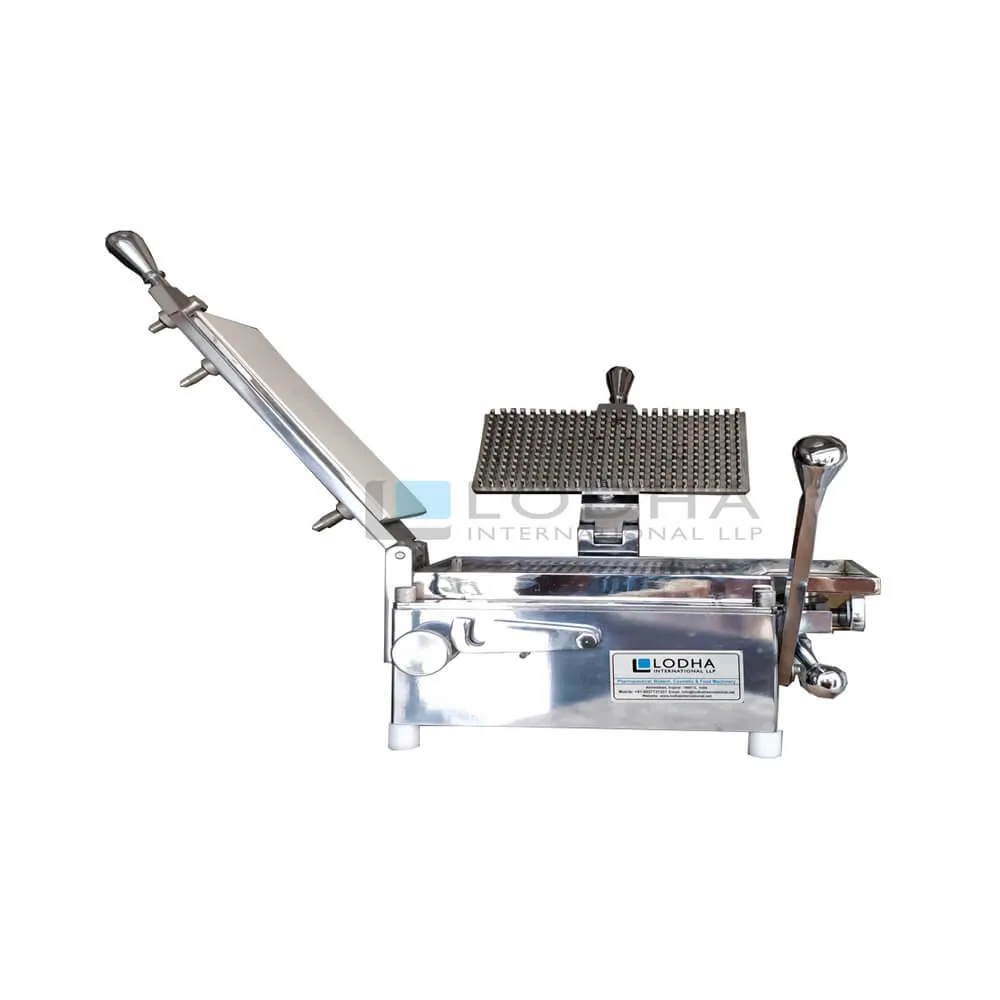

Manual Capsules Filling Machines

As the pharmaceutical industry evolved, capsules became popular and there was need for a faster way to package capsules which led to invention of the Manufacturer of manual capsule filling.

The machine is best suited for small to medium batch size production requirements and a wide range of products can be made using this process. The manual capsule filler is able to fill and close hard gelatin capsules containing powders and granules.

Capsule filling machines are an automatic device that has been propelling various industries such as pharmaceuticals, cosmetics, and food industry, etc. for years. Encapsulators or capsule fillers are put on work to fill empty capsules made of gelatin with powders, granules, semi-solids, liquids substances, etc. These ingredients comprise API or active pharmaceutical ingredients or a mixture of active drug substances and excipients. Thus this whole process of filling in the empty capsules is often termed as Encapsulation.

With the advancement in technology, there have been multiple types of filling machines devised to increase the rate of production. The new encapsulators include Manually operated encapsulators, semi automatic encapsulators, and Automatic Encapsulators.

Manually operated machines possess a bed of around 200 to 300 holes, a loading tray with 200-300 holes and a powder tray. Other important segments of this machine include a pin plate, a sealing plate with a rubber cap, and a lever. A handle with a loading tray encircled with 250 holes on an average is capable of producing around 6250 capsules per hour. Small scale manufacturers and hospitals utilize this type of encapsulators for extempore preparations.

Important Features of Manual Capsule Filling Machine

- Large number of capsules can be filled per hour depending on machine design and model.

- Different models are available for various clients based on their manufacturing needs.

- Equipment designed to handle a wide variety of capsules.

- Easy mounting and user friendly operation and parts replacement hence very low down times.

- Easy assembly and disassembly for cleaning and maintenance purposes.

- The equipment is fully washable as per the good manufacturing practices (GMP) rules.

- Newer improved designs have negligible final product rejections and ensure better return on investment.

- Contact parts made of stainless steel and non corrosive materials to eliminate contamination and easy cleaning.

- Long life and trouble free operations.

- Table and partial filling attachments can be offered to fit the specific needs of the business and specific formulations.

- High quality loading plates.

How are capsules filled by manually operated machine?

In the case of manually operated machines, the two parts of the capsules are detached and are inserted into the loading tray and its front knob is checked. The empty capsules are poured with the filling materials and then sealed off. The locking lever is forwardly pulled. There is a long handle that is given with a provision of lifting off the caps from the bodies. Post this stage, capsule bodies are brought at the same level as the filling surface. The Powder to be filled inside is priorly measured and the rest of the ingredients are moved to the shelf. The capsules are filled with the powder. The machine can even compress his powder if required. Once the capsules are filled with the filling material these are forwarded to the next stage which is sealing off the filled capsules. It is now moved to the stage for locking. The part handling the bodies is pushed back into caps all at one time thus locking up the capsules. The capsules are now arranged over a tray to exit the machine for packaging. Vacuum assisted and Double slide methods are the two common methods applied for the filling up the capsule.

Such machines are extremely durable for capsule filling and prove themselves reliable in the maintenance of the integrity of the filled capsules. Its output is approximately up to 55000 to 60000 capsules per hour and it can produce varying sizes of capsules ranging from type 00, 1,2, 3, 4, and 5. The length and width of the capsule can be in the range of 400mm and 300mm respectively. The machine provides an extra slot for an additional attachment of equipment as an online capsule polishing machine, dust extractor, damage capsule sorter, and an empty capsule ejector.

Therefore these machines as they have been described above are beneficial in increasing the production manifold. Pharmaceutical is one of the major industries that need to generate such capsules on a daily basis. Technological upgradation has thus shifted manual production to machine production.

Operational Steps

The manual capsule filling machine has three basic steps which are:

- Fitting the empty capsules into the machine

- Filling the capsules with powder

- Covering the capsules.

This simplicity of operation and the moderate output has made the machine very suitable for:

- A large variety and low volume encapsulation operations

- Small manufacturing units

- Hospitals and pharmacies

- Filling of formulations and RND laboratories, Pharmacy training institutions and herbal medicine manufacturers.

The non contact parts of the manual capsule filler, on the other hand, are manufactured using mild steel and hard chrome plated for an aesthetic look. A 300 Holes Manual Capsule Filler is potent enough to handle difficult powder and products.

The manual capsule filling machine has evolved from simple design making few capsules per hour to huge production outputs and as such can be used commercially. Some of the important advantages of this equipment include simplicity in design, hygienic, accurate and precise operation, durability and cost effectiveness for small to medium scale operation.