Get in touch! +91 9687731331 | +91 9687631331 | info@lodhapharma.com

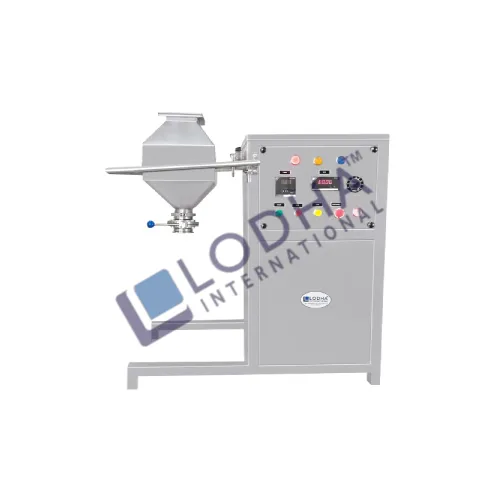

R&D Lab Octagonal Blender

Lodha International LLP is the leading manufacturer of R&D Lab Octagonal Blender, offering a powerful and capable mixing device designed for pharmaceutical applications and research laboratories. This innovative octagonal blender machine is consistently blending and lubricating dry grains and granules. The unique octagonal shape of the container allows materials to enter from eight different sides, reducing the required rotations per minute while maintaining continuous movement for thorough mixing. Ideal for crystalline and granular substances, the pharmaceutical octagonal blender is particularly useful in healthcare, beauty, and cosmetics industries. For optimal results, users should fill the blender to about two-thirds capacity.

The octagonal blender R&D lab equipment offers significant advantages over traditional cone blenders. It’s slow rotation speed and eight-sided design create a more uniform blend, making it perfect for delicate granules and sensitive materials. As a top octagonal blender manufacturer, Lodha International LLP has developed this equipment to meet the highest standards of quality and efficiency. Whether you need an octagonal blender in pharmaceutical industry settings or for other applications, this machine delivers consistent and reliable results. The octagonal blender machine manufacturer and exporter provides a solution that simplifies the mixing process while maintaining product integrity, making it an invaluable tool for various industries requiring precise blending capabilities.

Salient Features of R&D Lab Octagonal Blender:

Process Operation of R&D Lab Octagonal Blender

The powder is filled up to two-thirds of the blender's volume for proper mixing. As the blender rotates continuously, the material inside moves in a complex and vigorous manner, resulting in uniform mixing. The conical shape at both ends helps achieve even mixing and makes it easier to discharge the mixed product. The blended product can be discharged from the bottom of the blender using a butterfly valve. This high-quality blender operates smoothly and efficiently, providing reliable and trouble-free performance throughout the mixing process.

Technical Specification of R&D Lab Octagonal Blender:

| Model | LI-OB 5 | LI-OB 10 | LI-OB 15 |

| Gross Capacity | 5 Litre | 8 Litre | 15 Litre |

| Working Capacity | 2 Litre | 4 Litre | 10 Litre |

| MOC (Material of Construction) | SS316/SS304 | SS316/SS304 | SS316/SS304 |

| Design Type | Cantilever | Cantilever | Cantilever |

| Design Feature | Interchangeable Bowl | Interchangeable Bowl | Interchangeable Bowl |

| Drive | 0.5HP, 1440RPM, 3Phase, NFLP | 0.5HP, 1440RPM, 3Phase, NFLP | 0.5HP, 1440RPM, 3Phase, NFLP |

| Power Voltage | 440V, 3Phase, 50Hz | 440V, 3Phase, 50Hz | 440V, 3Phase, 50Hz |

| * Power voltage can be adjusted as per customer’s domestic power voltage requirements. * Rights of technical improvements & modification reserved. * Illustrations & dimensions are shown for information purpose only. |

|||