Get in touch! +91 9687731331 | +91 9687631331 | info@lodhapharma.com

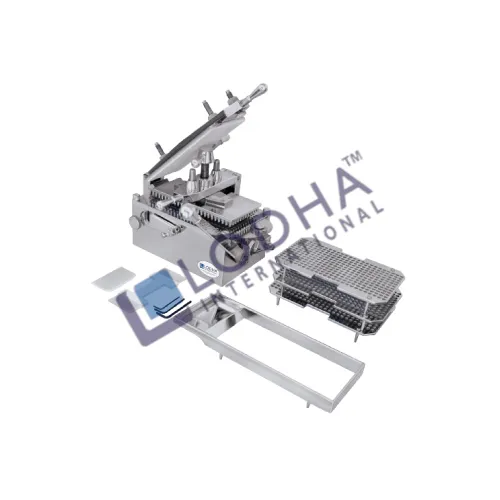

Lodha International LLP is the leading manufacturer of the R&D Lab Bench Top Capsule Filling Machine. This compact and capable capsule filler is designed for filling and sealing hard gelatin capsules, making it ideal for various industries, including pharmaceutical, cosmetic, food, veterinary, biotech, and allied sectors. The manual capsule filling machine is available in a GMP model, constructed entirely of stainless steel (SS304/SS316), and a standard model with a hard chrome-plated base. Cost-effective and efficient, this capsule filling machine can fill between 6,500 and 7,000 capsules per hour, making it perfect for the small-scale production needs of clinical research organizations and specialty laboratories.

As a premier bench top capsule filling machine manufacturer, Lodha International LLP provides reliable and high-quality equipment. Our automatic bench top capsule filler machine is known for its adaptability and ease of use. It's a cost-effective solution for R&D labs needing quality and performance in capsule filling. Lodha International LLP, a leading manufacturer of bench-top capsule filling machines, offers equipment that meets the various requirements of various industries, supporting both standard and specialized applications.

Salient Features of R&D Lab Bench Top Capsule Filling Machine:

Process Operation of R&D Lab Bench Top Capsule Filling Machine

The operation of the capsule filling machine follows a systematic, step-by-step process. First, colorless and translucent capsules are positioned in the capsule filling tray. The machine then separates the caps from the bodies of the capsules. Next, the capsule bodies are filled with the desired pharmaceutical ingredients. Once filled, the machine rearranges the caps and bodies together. Finally, the filled capsules are expelled from the machine, ready for use. This method of operation is common across different types of capsule filling machines, also known as encapsulators.This structured approach improves quality and performance, making the automatic bench top capsule filler machine a valuable asset for labs and production facilities. It's easy-to-use design and strong features make it a reliable choice for various capsule filling applications.

Technical Specification of R&D Lab Bench Top Capsule Filling Machine:

| Model: | Up to 6000 Capsules/ hour |

| Capsule Combination | Size 00, 0, 1, 2, 3, 4 & 5 (through different machines & parts) |

| Sequence of Holes | 25X12=300 |

| No of Loading Trays | 3 Nos |

| Overall Dimension | 405mmX300mmX455mm |

| Net Weight | 43Kg Approx. |

| Gross Weight | 50Kg Approx. |