Get in touch! +91 9687731331 | +91 9687631331 | info@lodhapharma.com

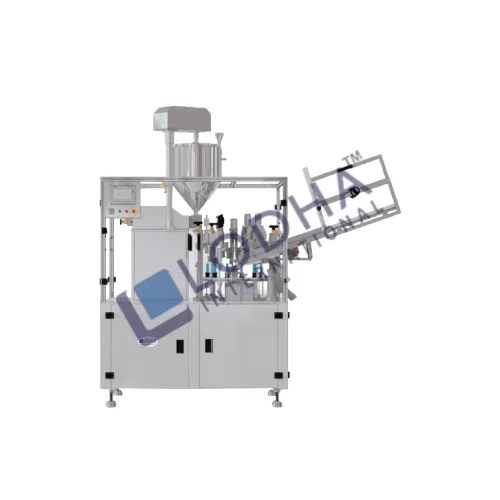

Aluminium Tube Filling Machine

Lodha International LLP is the top aluminium tube filling machine manufacturer, providing innovative solutions for the pharmaceutical industry. Our best aluminium tube filling machine is designed specifically to offer a clean and efficient filling procedure. Its interchangeable sections allow it to handle a variety of tube sizes and shapes, making it versatile for different batch sizes. The machine’s precision filling methods make sure fast, accurate filling, producing superior end products. This makes it ideal for filling semi-solid items like cream filling, gels, toothpaste, and other products into plastic or aluminum tubes.

Tubes are placed manually in the machine's holding cups. Once the tubes are filled, they are sealed and then sent out through the discharge hopper. The filling volume can be easily adjusted to meet the required specifications. The machine features a thermo heat sealing device for PVC tubes and a folding and crimping device for aluminum tubes. After sealing, the area can be coded using a coding device. Additionally, compressed air is used to flush out any dust from the tubes before filling, ensuring a clean and hygienic operation.

Salient Features of Aluminium Tube Filling Machine:

Process Operation of Aluminium Tube Filling Machine

The aluminium tube filling machine from Lodha International LLP offers an improved and efficient process operation designed to meet the highest standards of the pharmaceutical industry. The process begins with manually placing the tubes into the machine's holding cups. Once securely in place, the machine automatically feeds the tubes to the filling station. Here, precision filling methods make sure each tube is accurately filled with the specified amount of product, whether it's cream, gel, or toothpaste. After filling, the machine utilizes a thermo heat sealing device for PVC tubes and a folding and crimping device for aluminum tubes to make sure a secure seal. The machine's user-friendly interface allows for easy adjustment of the filling volume to match specific requirements. Integrated safety and overload devices make sure smooth operation, while the PLC’s touchscreen control system provides real-time monitoring and troubleshooting.

Technical Specification of Aluminium Tube Filling Machine:

| Specification | LI-STF 8 | LI-TUBO 12 |

| No. of Filling Head | Single | Single |

| No. of Station | 8 | 12 |

| Production Output (Per Min) | 25 - 30 tubes | Up to 50 tubes |

| Tube Diameter | 12mm to 50mm | 12mm to 50mm |

| Tube Length | 50mm to 200mm | 50mm to 200mm |

| Tube Loading System | Manual | Automatic |

| Tube Orientation | Manual | Automatic |

| Filling Range | 3gm to 250gm** | 5gm to 250gm** |

| Compressed Air Requires | 6 CFM | 12 Bar |

| Power Consumption | 1 H.P. | 1 H.P. |

| Electric Characteristic | 440V, 3 Phase, 50Hz, 4 Wire System | 440V, 3 Phase, 50Hz, 4 Wire System |

| Net Weight | 250 Kgs. | 465 Kgs. |

| Gross Weight | 375 Kgs. | 580 Kgs. |